Comprehensive Printing Solutions

Explore our wide range of high-quality printing services,

including digital, screen printing, and more.

From custom apparel to unique accessories, we deliver precision and creativity in every project. Let Teeprints bring your vision to life with exceptional printing expertise.

Screen Printing

Screen printing is a well-established technique for creating custom designs on fabrics. It’s known for its durability, affordability for larger quantities, and ability to handle a wide range of colors and effects. Here’s a closer look:

The core idea: A mesh screen with a stencil of your design is used to transfer ink onto the fabric. The ink is forced through the open areas of the screen, leaving a sharp image on the garment.

Screen printing is a reliable and cost-effective choice for producing large quantities of durable, custom-printed garments. It offers vibrant colors and the potential for special effects, making it a popular choice for businesses and organizations.

DTF Printing

DTF printing is a versatile technique that allows you to print full-color designs onto a wide range of fabrics, including cotton, polyester, blends, and even non-traditional materials like leather. Here’s a breakdown of the process:

The core idea: Instead of printing directly on the garment, DTF prints your design onto a special PET film first. Then, the design is transferred from the film to the fabric using heat and pressure.

Advantages of DTF printing:

- Versatility: Works on a wider range of fabrics compared to some other methods (like DTG which is mainly for cotton).

- Vibrant colors and details: DTF produces high-quality prints with crisp details and a broad color gamut.

- Durable and washable: DTF prints are resistant to cracking, fading, and can withstand multiple washes.

- White ink capability: DTF printing allows for white ink printing, enabling vibrant designs on dark-colored fabrics.

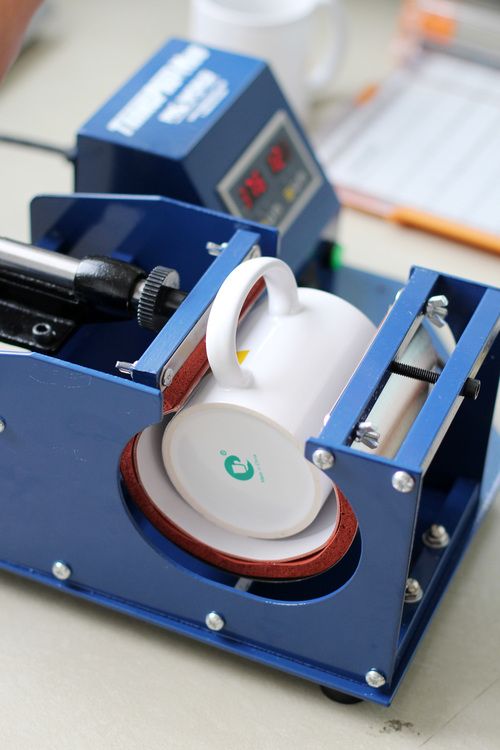

Mug Printing

Mug printing allows you to personalize mugs with designs, logos, photos, or text. There are different techniques for mug printing, but a popular choice for its versatility and durability is dye sublimation printing. Here’s an overview:

The core idea of dye sublimation:

- Image preparation: Your design gets printed onto special transfer paper with sublimation inks.

- Heat transfer: The transfer paper is placed on the mug, and a heat press is used to apply high heat and pressure.

- Dye transformation: Under heat and pressure, the sublimation inks transform from a solid state to a gas, becoming embedded directly into the mug’s coating.

- Cooling and solidification: As the mug cools, the dye solidifies, creating a permanent and vibrant design that becomes part of the mug itself.

Things to consider with mug printing:

- Mug material: Sublimation works best with specially coated mugs designed for the process.

- Minimum order quantity: Some printing services might have minimum order requirements for mugs.

Overall: Dye sublimation mug printing offers a fantastic way to create personalized mugs with high-quality, long-lasting designs. It’s perfect for creating custom mugs for personal use, gifts, or promotional purposes.

Sublimation Printing

Sublimation printing is a unique process that utilizes heat and pressure to transfer dye onto various materials, particularly polyester fabrics and specially coated items. It delivers stunning results with a high degree of permanence.

The Sublimation Printing Process:

- Design Creation: Your design is digitally created on a computer.

- Printing onto Transfer Paper: The design gets printed in reverse on special sublimation paper using sublimation inks.

- Heat Press Transfer: The transfer paper is placed on the chosen material, and a heat press applies high heat and pressure for a specific time.

- Dye Sublimation: The heat transforms the inks into gas, which then penetrates the material and solidifies upon cooling, creating a permanent bond.

Embroidery Printing

Embroidery is the art of decorating fabric or other materials with needle and thread. It’s a time-tested technique that can create intricate designs, logos, lettering, or even detailed pictures. Teeprints.in likely offers embroidery services using computerized embroidery machines, ensuring precision and efficiency.

The Embroidery Process (for Machine Embroidery):

- Design Digitization: Your desired design is converted into a digital format that the embroidery machine can understand. This involves specifying stitch types, thread colors, and placement.

- Machine Setup: The embroidery machine is threaded with the chosen colors based on the digital design. Stabilizers might be used to hold the fabric taut during the stitching process.

- Embroidery Process: The machine automatically guides the needle, following the programmed pattern and creating the design on the fabric.

Ready to get started?

Printing at your fingertips everything you need under one roof!