Introduction

Screen printing has been around for decades — yet myths about it still flood conversations.

Some say it’s outdated. Others believe it’s only for bulk orders.

The truth? Screen printing is still one of the most reliable, vibrant, and durable printing techniques available.

Whether you’re printing for a small business, an event, or a clothing line, understanding the facts can save time, money, and frustration.

Myth 1: Screen Printing Is Outdated

Reality: Far from it!

Screen printing has evolved dramatically with advanced inks, automation, and hybrid digital integrations.

Today’s printers combine traditional craftsmanship with modern precision, allowing for vibrant colors, better registration, and consistent results.

Many top fashion brands still rely on screen printing because of its durability, vibrancy, and texture quality.

Myth 2: It’s Only for Large Orders

Reality: While screen printing is efficient for bulk runs, many shops now handle small-batch and custom orders with the same care.

Automation and pre-coated screens make small runs more affordable than before.

If you’re printing uniforms, team tees, or a few branded hoodies — screen printing can still be a cost-effective choice.

Myth 3: You Can Only Print on Cotton

Reality: Modern screen printing inks work on cotton, polyester, blends, and even nylon.

Water-based inks and specialty adhesives now make it possible to print on various textures and performance fabrics without compromising quality.

You can even combine it with DTF Printing or Sublimation Printing for complex multi-surface designs.

Myth 4: Colors Always Crack or Fade

Reality: Cracking happens only when prints are poorly cured or low-quality ink is used.

Professional printers ensure proper heat curing and ink layering, making the print last as long as the garment itself.

With proper care — gentle washing, no harsh detergents, and air drying — screen-printed designs stay vibrant for years.

Myth 5: Screen Printing Can’t Handle Complex Designs

Reality: Modern equipment and software allow fine details, gradients, and photographic effects to be printed with precision.

Techniques like simulated process printing and halftones bring digital-quality designs to life on fabric.

If your design has high detail, consult your printer about screen mesh count and ink type — they’ll guide you on how to achieve the best output.

Myth 6: It’s Expensive Compared to Other Methods

Reality: The setup cost may be slightly higher due to screen preparation, but the per-piece price drops significantly with quantity.

That’s why screen printing is still the go-to for uniforms, event wear, and promotional merchandise.

When compared to digital or sublimation methods, screen printing often wins on large-scale cost efficiency and ink durability.

Myth 7: Screen Printing Isn’t Eco-Friendly

Reality: Many shops now use eco-friendly, water-based inks and energy-efficient dryers.

Reusable screens and biodegradable cleaning solutions have also made this process far greener than in the past.

Some printers even integrate solar power into their production units — making sustainability a key part of the printing process.

Tips for First-Time Customers

If you’re new to screen printing, keep these tips in mind:

- Provide high-resolution artwork (300 DPI preferred).

- Choose fabric colors that complement your design.

- Ask for a test print or proof before bulk production.

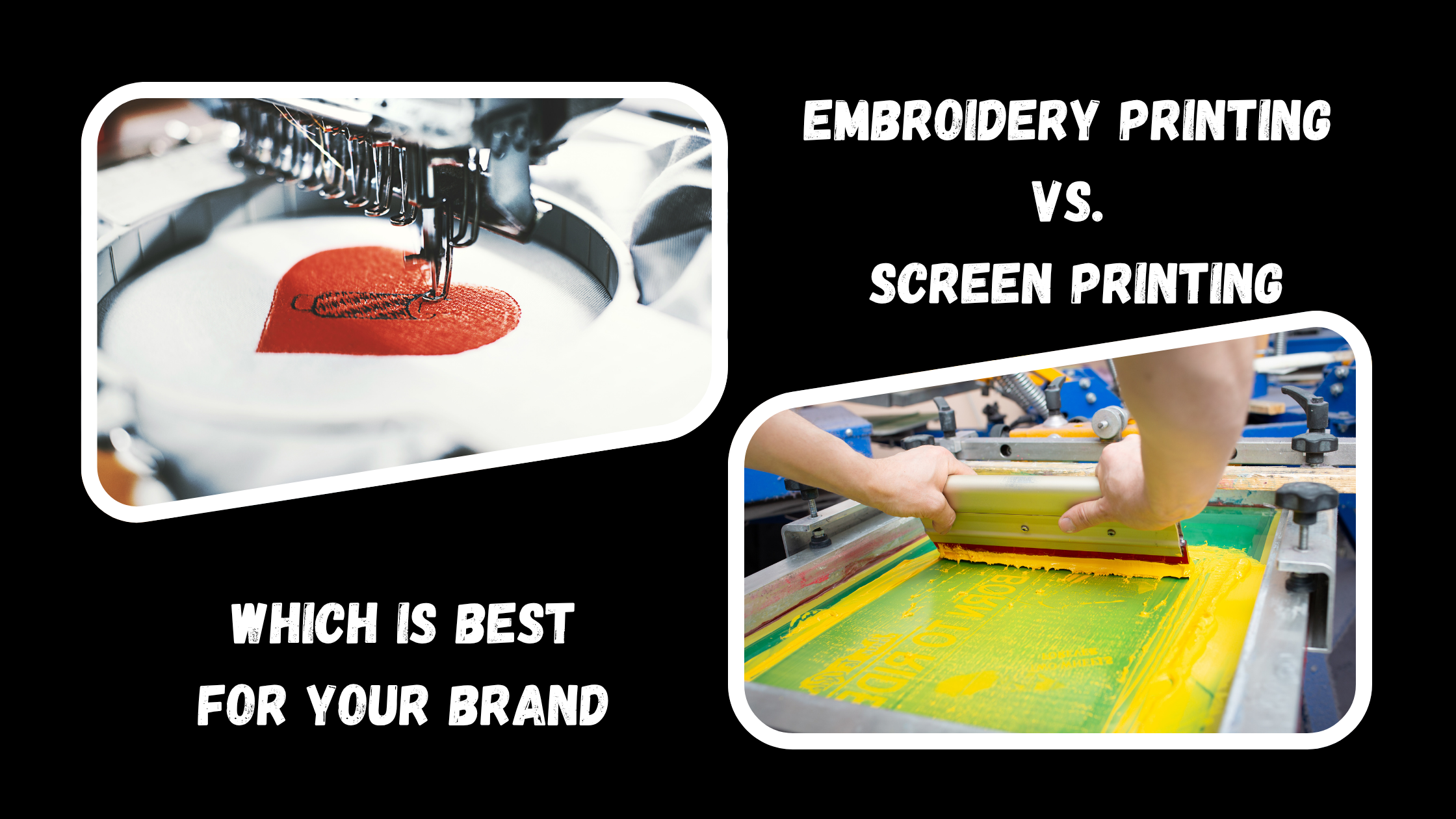

- Discuss your print method — screen printing, DTF Printing, or Embroidery Printing — to find what fits your vision.

Conclusion

Despite all the myths, screen printing remains one of the most versatile and reliable printing techniques in the apparel industry.

It’s cost-effective, scalable, and capable of producing premium-quality designs that last.

Understanding the truth helps you make smarter choices — and ensures your first printing experience is smooth, satisfying, and successful.When it comes to making designs that last, screen printing still holds the crown.